Vapour Barrier Suspended Timber Floor Construction Detail

A vapour barrier can easily be realised with a plastic foil like polythene at least 0 2 mm thick.

Vapour barrier suspended timber floor construction detail. 09 timber flooring design guide page 6 1 timber flooring and floor finishes 1 1 movement in timber floors prior to discussing timber flooring products it is important to understand the relationship between timber humidity in the air surrounding it and the dimensional changes that occur as the result of changes in humidity. Some people and organisations will refer to the material that controls vapour movement as a vcl and some will call it a vapour barrier. Hi i did just like to check my plan for installing some insulation in a timber joisted suspended wooden floor in a 1900 ish terraced house. Effectively a thick plastic sheet a damp proof membrane dpm is used to create a barrier between a concrete or screed subfloor and a wood floor.

My plan is to remove the floor boards using some scaffolding netting stapled between the joists up and over up and over to hold some fibreglass insulation clean out any excess rubble and double check the air bricks. Water vapor can pass through building materials in several ways including direct transmission and by heat transfer but studies suggest that fully 98 percent of the moisture transfer through walls occurs through air gaps including cracks around electrical fixtures and outlets and gaps along baseboards. Thus installing vapor barriers on wall surfaces must. To answer your question introducing a vapour barrier to the underside of the floor joists would be a complete waste of time that is other than to assist in the air tightness of the building which is another bone of contention whereas introducing a vapour barrier over the top of the floor joists may well provide some long term benefits by.

The seams must be sealed with tape and the edges of the foil should overlap a little a few inches. A damp proof membrane or dpm is a waterproof barrier that s introduced between your sub floor and your wood floor. That leaves an opening to improve moisture management and airtightness by fitting a tyvek membrane and carefully sealing the gaps and joints. Previously floor timbers had been prone to damp and rot thanks to their direct contact with the moist ground.

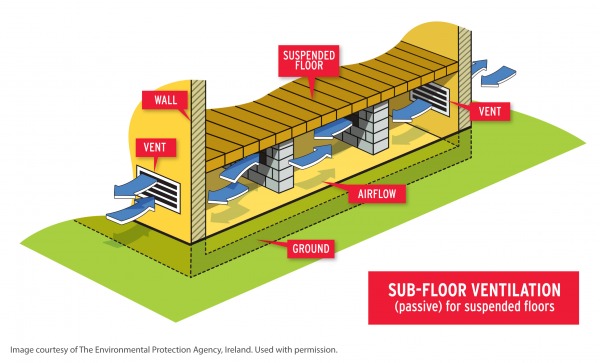

This barrier is intended to stop moisture passing from one to the other. It is important to remember that no material is completely vapour proof so the term barrier can be slightly misleading. Suspended timber floors required under clause h1 energy efficiency. At the turn of the 18th century when construction techniques moved from boarded floors installed directly on the ground to suspended timber floors over a ventilated chamber the innovation solved a significant problem.

However vapour barrier specification and details together with those for dpc and dpm are only mentioned in relation to the two generic floor construction types of suspended timber floors and concrete slab on ground in e2 as1 section 10 0 floors. Moisture management for suspended timber floor construction many suspended timber floor constructions have discontinuous insulation between the joists.